Stitch Glue Boat Design Software

HARRIS owns Chesapeake Light Craft, the Annapolis-based purveyor of wooden boat kits and plans. His long tenure at CLC was preceded by a passion for boatbuilding and small craft that stretches back to earliest childhood. His first successful design was launched at age 14. More paddling, rowing, and sailing craft followed quickly, though he paused to get a degree in music—his second passion. After college he was determined to make a career as a boatbuilder and designer in the esoteric world of wooden boats. Eighteen years later, he’s shipped 24,000 boat kits and seen his designs built in more than 70 countries. His work as a designer and builder ranges from dinghies to large multihulls and from kayaks to powerboats.

He lives on the shores of Chesapeake Bay near Annapolis with his wife, daughter, and an always-changing fleet of curious small boats. Close Tuition: $800 Note: This is a five-day course ending Friday afternoon. The “stitch-and-glue” construction method is the easiest way to build a boat, as tens of thousands of amateur boatbuilders will testify.

The approach, which emphasizes the use of epoxy adhesives and strategic fiberglass reinforcement combined with marine plywood, is ideal for first-timers. But like so many things, it’s easy to do but hard to do well. This class is about how to do it well. The stitch-and-glue techniques date back to the advent of modern adhesives in the 1960s. The basic process involves prefabricated plywood parts, which are stitched together with loops of wire, then glued with epoxy to create rigid and seaworthy hulls. The process dispenses with lofting, elaborate molds, and much of the complex joinery of traditional wooden boat building.

While the method is beloved of amateurs, in recent decades professionals have seized on this type of construction as a way to create beautiful free-form hull shapes with amazing strength and light weight. While still benefiting from the speed and ease of stitch-and-glue boatbuilding, pros deploy sophisticated techniques that result in optimized structures and glittering finishes.

If you are going to build a boat, you'll want one worthy of your investment. Read the reviews: best wooden kayak and stitch and glue kit. A great free software for ship building: Delfship: stich and glue method delfship: small wooden boat free plans 2011-2015.

As the owner of Chesapeake Light Craft, John Harris has shipped 26,000 stitch-and-glue kits and built hundreds of boats in classes and in his own shop. In this class, students will build an attractive, 13′6″ peapod of Harris’s design. This traditional and popular design offers many opportunities to focus on the finer points of stitch-and-glue, including perfectly hand-drawn fillets that look like they were molded in place; fast and clean fiberglass sheathing and reinforcement; the use of advanced materials like peel-ply, and hollow wood-epoxy spars.

Whether you’re building your first boat, or looking to learn the advanced tricks that the professionals use to get “showboat” finishes, this one-week class will advance your abilities to work with wood, epoxy, and fiberglass. And the boat we build together will be raffled off at the end of the week to one very lucky student! John Harris has a wealth of knowledge in boat design and construction techniques for building stitch-and-glue boats. He shared all of this with his students through daily, practical lessons, lectures, and demonstrations.

The course was very well suited for both the novice and experienced boatbuilder.” J.M., Brick, New Jersey 2018 Boatbuilding & Woodworking Courses. John Harris is an excellent instructor. He’s not only very experienced and knowledgeable but very generous with his time and information. I signed up for STITCH-AND-GLUE CONSTRUCTION to build up my confidence working with epoxy and fiberglass. I was able to do just that and so much more.” D.H., Buenos Aires, Argentina John Harris is top notch. He explained all the material in detail, and challenged each student to get the most out of the STITCH-AND-GLUE BOATBUILDING course.

It definitely expanded my knowledge of plywood/epoxy construction.” E.R., Plainview, New York.

Stitch and Glue Ply This is normally restricted to cartop and trailable boats, where ply thickness of up to around 6 mm can be used. For the smaller boats the panels are plain ply. Larger boats can be built with the panels in thin ply, then GRP sheathing applied both internally and externally, generating a sandwich construction. This technique is regarded as giving faster and less demanding construction than ply on frame. This will be because framing is not required (or isolated framing is fitted to the built hull shell), and for the larger sizes the shaping and fitting of thick ply is avoided.

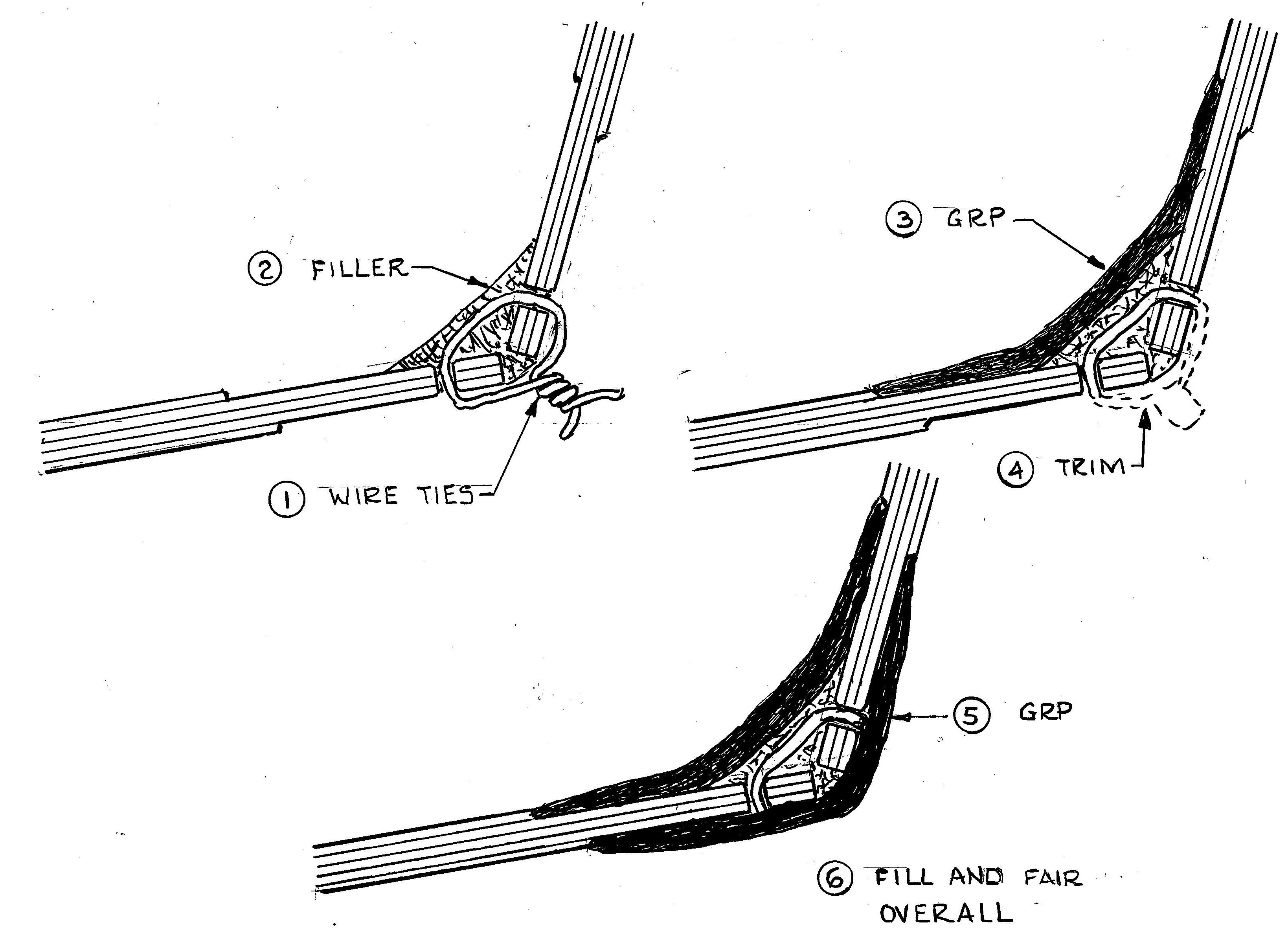

Many recent applications of ply stitch and glue techniques have been for timber epoxy construction, or as the basis for GRP/ply sandwich construction. This latter allows thicker panels to be built, to suit larger boats. Normally the ply panels are cut out to their installed shapes, and progressively pulled together along their longitudinal seams (stem/keel and chines), with copper wire (or recently plastic cable ties) through holes. This progressively generates and controls the hull shape, which can be adjusted to some extent prior to the fitting of framing. A basket frame can be used to help generate the shape, and support the hull (right way up) during construction. Flared bow shapes can be generated by making a series of slender V cuts longitudinally in the topside panels.

3d Boat Design Software

These will generate near-flat joints. Seams are then filled and glassed internally. The copper wire are then trimmed back externally, and the seams are glassed externally. External and internal faces are glassed as required. Gunwales, internal framing etc are added as required, and the outer and interior surfaces smoothed and then coated as required.

Stitch and Glue Joints Convert a Design to Stitch and Glue If there is a design you would like to build, but it lacks the panel shape information, all is not lost. (I am assuming you have some familiarity with the stitch and glue technique and with boat hull shapes.) I haven’t tried this, so at ths stage you are on your own. Get a copy of 3DBoatDesign software ($50 nominal), install it, and get some familiarity with it. Enter the hull shape of your chosen design into 3DBoatDesign. Adjust your hull shape to achieve fully developable surfaces. (This is a feature of 3DBoatDesign.). Output the shapes of the hull panels from 3DBoatDesign.

I will offer procedure on this when I have tried this). Mark out the panel shapes onto the ply sheets. You are on your own for positioning the ply panel butts and the nesting. Cut out the ply panels, and proceed with building your boat.

Small Boat Design Software

Go to Boat Design Software page for 3DBoatDesign information – Tutorial There is a well illustrated tutorial on Stitch and Glue construction under “Tech Support” on the Bateau website. This is well worth a viewing if you are considering the technique. Click here to go to the Bateau website. Go to Stitch and Glue Ply Blog page – The Major Plan Supplier Bateau (E-Boat Inc) has an extensive range of boats, all using this technique.

Go to Bateau page –. Go the Bateau website – click here.